Quality Assurance

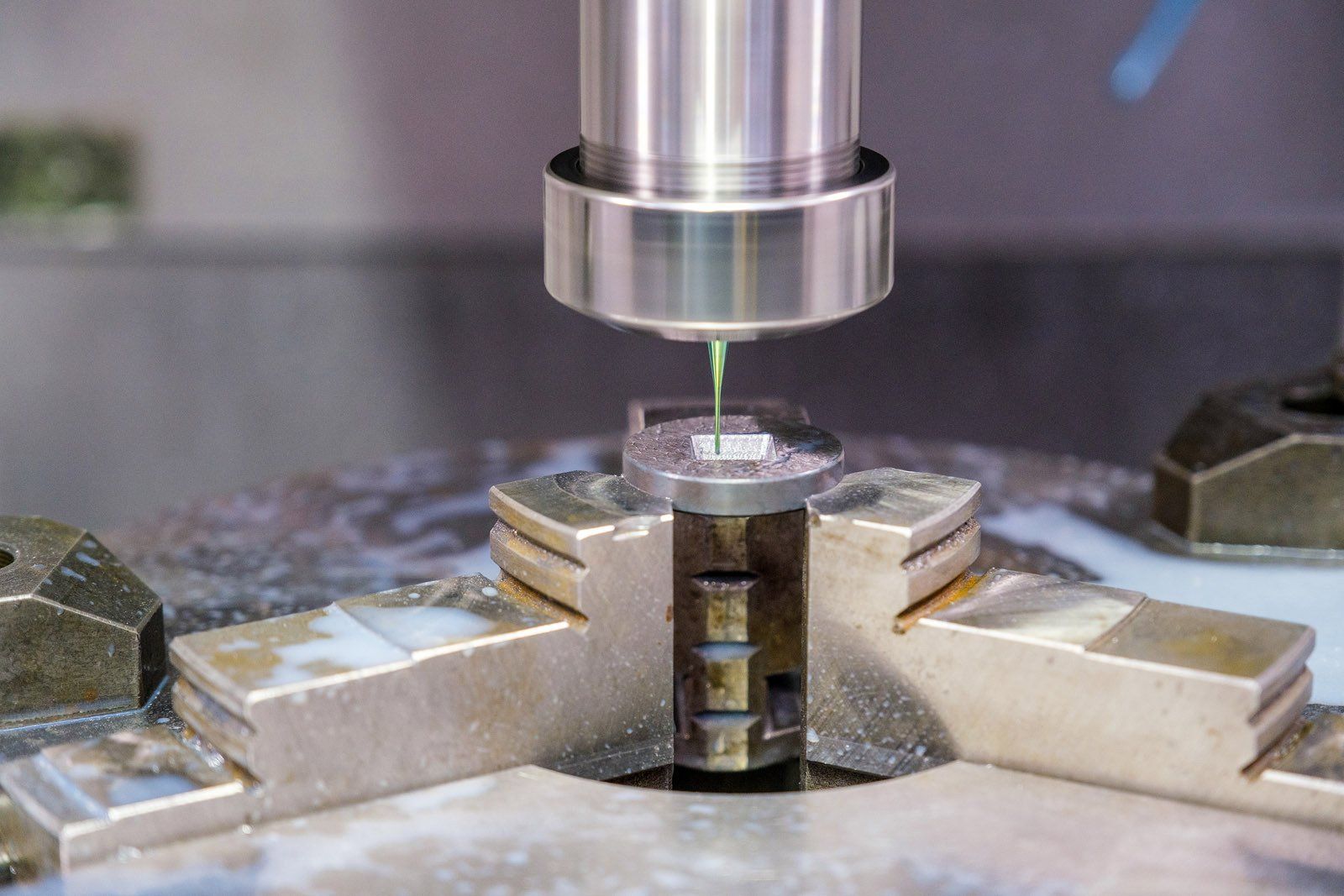

We try to manufacture to the highest standards using the most effective and safe manufacturing techniques, while maintaining lowest cost and highest customer satisfaction.

We know that our commitment to training and education towards our staff is a key player in achieving the high standards that we've set for ourselves.

While maintaining international standards we try to exceed them and set new standards for ourselves.

Through out the supply chain, from manufacturing to customer service, we have taken honesty and loyalty as our guide in setting out our name and being known as a trustable supplier.

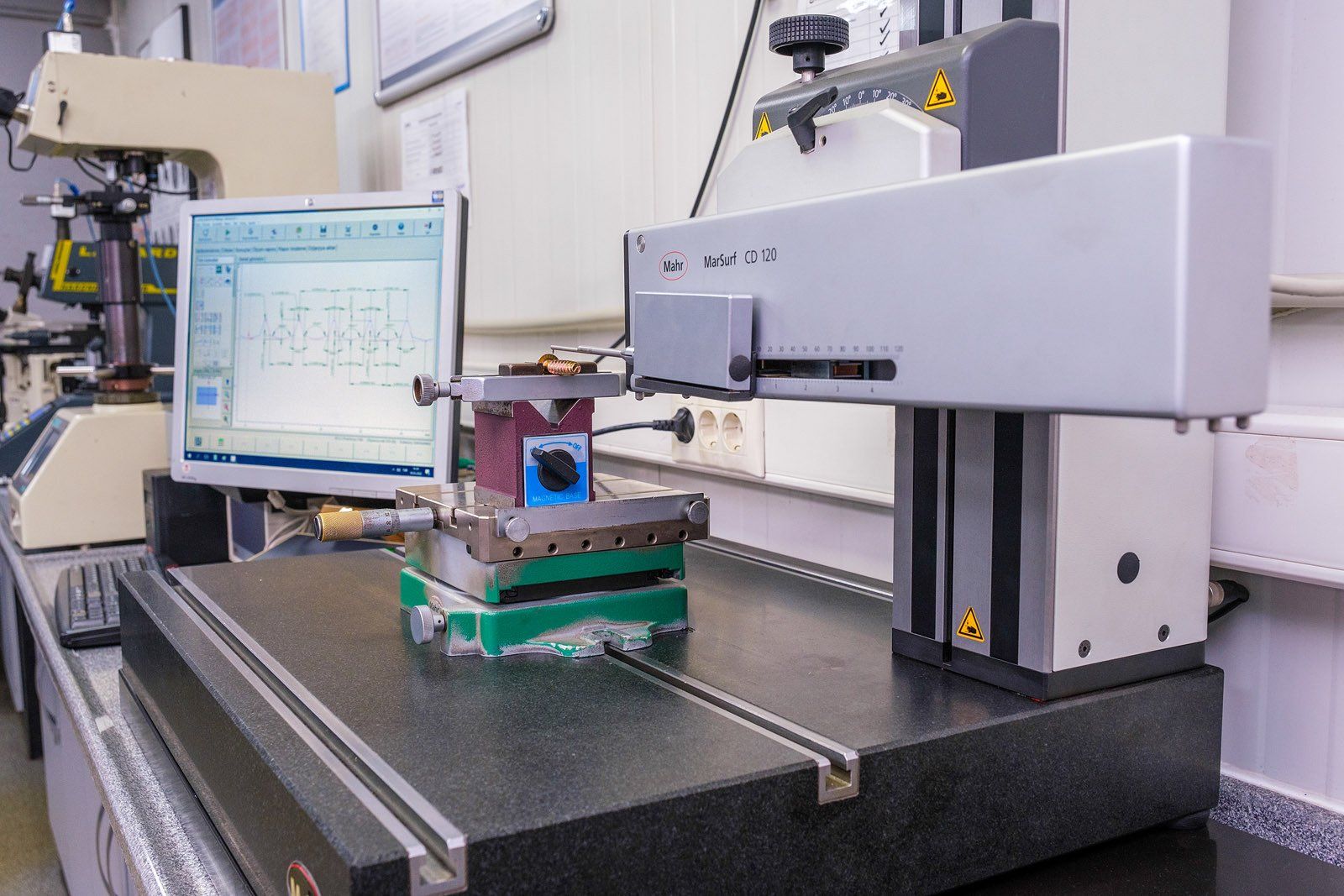

We use the following equipment in our quality control lab:

Mechanical: HV/HRC/ Hardness, Dynamometric Range, Tensile Test, Tinius Olsen 650, Innovatest Falcon 800 Micro Vickers Hardness Tester, Mahr Contour Measuring and Surface Rougness Measuring Device, Concentricity Mesauring Device, Digital Torque Measuring,

Chemical: Salt Spray Chamber, Bowman Xray Coating Thickness and Chemical Analysis device, Schatz KistleR Coeeficient of Friction Device

Metallographic:

Nikon Epiphot Microscope, Struers Mounting Press, Struers Cutting, ATM Grinding and Polishing Machine , Mitutoyo Projector, Easson Vision Control, Innovatest Metallograpic Analysis Software